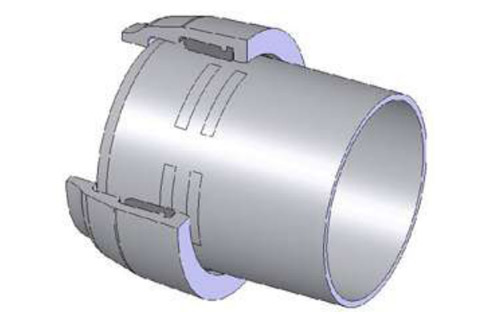

Socket and Spigot Flexible Joints are assembled with synthetic EPDM (Ethylene Propylene Diene Monomer) / SBR (Styrene Butadiene Rubber) rubber gaskets of special shape - the gasket has a hard ‘Heel’ and a soft ‘Bulb’.

In Push-on joints, the soft bulb of the rubber gasket is compressed when the spigot is inserted into the socket.

The 'heel' locks the position of the gasket and does not allow the gasket to get displaced when the spigot is pushed in.

The joint becomes tighter with the increase in internal pressure of water. The rubber is confined in a place and cannot blow out.

Where it is necessary to deflect the pipeline from a straight line, either in the vertical or horizontal plane, deflection at the joint should not exceed the following:

| Push on Joint | Maximum Deflection Angle |

|---|---|

| 80-150 mm | 5° |

| 200-300 mm | 5° |

| 300-600mm | 3° |

| 700-800mm | 2° |

| 900-1000mm | 2° |