Electrosteel has a cast iron spun pipe manufacturing unit at Elavur, near Chennai in Tamil Nadu, which are manufactured as per IS:1536.

There are some specific applications in which cast iron pipes are being used like in certain new water supply works, sewerage pumping mains and old cast iron pipe replacement works. Thick-walled cast-iron pipes are also used for ash slurry handling.

Electrosteel Elavur unit is the largest producer of Cast iron spun pipes in India. The unit has ISO 9001 and ISO 14001 certification and this unit has installed capacity 9000 MT per month Cast Iron Pipes.

The Metallurgical Coke division at our Haldia plant was commissioned in 2005-06. Presently we produce 2,40,000 TPA/ annum. We also have a Coke Oven plant in our Srikalahasthi Works which has a capacity of 2,80,000 TPA / annum

Our Coke Oven plant at Haldia consists 4 batteries, with 131 horizontal waste heat recovery type ovens. The coke oven produces Low Ash Metallurgical (LAM) coke. Majority of this produce is consumed captively in our Blast furnace at Khardah plant. Apart from meeting captive requirement, we also sell in the market.

The waste heat of the coke oven gas is utilized for generating steam through waste recovery boilers. This steam is used for power generation at our captive power plant through efficient and environment friendly processes.

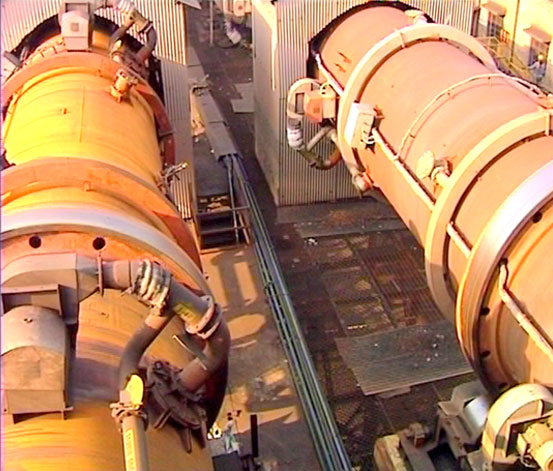

Direct Reduced Iron (DRI) / Sponge Iron Plant was commissioned during 2005-06 at our Haldia plant. This plant has two 100 TPD rotary kilns, with a total production capacity of 60,000 MT/Year, producing both pellet based and iron ore based DRI, which is suitable for Ductile Iron Pipe and steel making processes.

The majority of the production is used for captive consumption at our Khardah plant and the balance is sold in the domestic market.

Two waste heat recovery boilers are also connected to the kilns for environment friendly power generation.

Electrosteel commissioned its Ferro Alloy manufacturing unit at Haldia in mid-2019 with a capacity of 16000 TPA. Our products are suitable for steel making process and cater both to the domestic and export market.

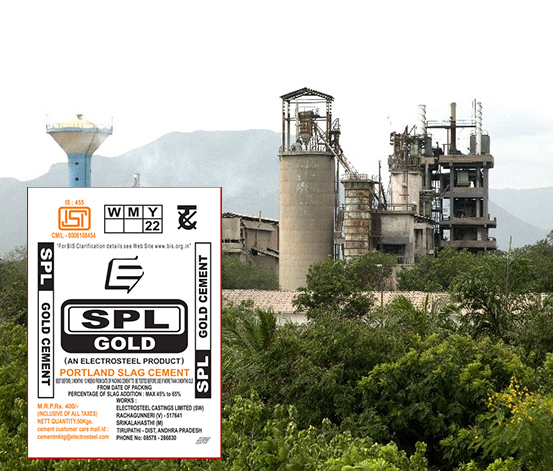

In order to utilize the slag generated from the Company's mini blast furnace, a mini cement plant was installed in the year 1995. The current capacity is 2,00,000 MT/Annum under the brand name "SPL GOLD". The plant today produces superior quality Portland slag cement conforming to IS 455: 2015. Also produces Sulphate Resistant Portland Cement confirming to IS 12330 and Ordinary Portland Cement confirming to IS 269.

SPL Gold Cement is manufactured by qualified and experienced technical team and stands for its quality.

Packed in both H.D.P.E (plastic) and PAPER bags, it is eco-friendly and ideal for all purposes.

We are having 2x9 MVA Submerged Arc Furnace. We are manufacturing Ferro Silicon Grades of 70-75% & 60-65% confirming to IS 1110 and have the capacity to produce Ferro Silicon of 16000 MTPA. We are committed to ensure highest quality standards to assure accurate and reliable product and service to our customers.

A dream, to lead in the Indian steel industry, led us to create Ferro Alloy products of the finest quality.

Manufacturing of Ferro Silicon is being done under the supervision of highly qualified professionals with precise chemical specifications. Our expertise lies in manufacturing Ferro Silicon in standard specification as well as customized form to meet with the specifications of our clients.

We have also obtained BIS license which is now mandatory to Purchase/ Sell Ferro Silicon as per Ministry of Steel.

We are having 450M3 Mini Blast Furnace, from which we are making 525000 MT Hot metal. The same we are utilizing for making DI Pipes and also Pig Iron. We are one of the most reputed manufacturers of Pig Iron in India, manufacturing basic and foundry grade Pig Iron which meets the requirement of Automotive Industries and CI/SG Iron Foundries.

Low Cost Pig Iron Manufacturers:

We are amongst the largest manufacturers of Low Ash Metallurgical Coke (LAMCOKE) in the country. The company has established a strong foothold in the LAMCOKE market by offering one of the best quality coke with the capacity of 2,80,000 TPA.

The Company offers a wide range of sizes of LAMCOKE with the help of its state-of-the-art coke ovens and screening plant. Also, the different types of blending processes adopted in the plant, help in enhancing the quality of the coke produced.